- NON-WOVEN GEOTEXTILE

- FIBERGLASS GEOGRID

- HDPE GEOMEMBRANE

- WATERPROOF LINER

- BIAXIAL GEOGRID

- WARP KINTTED POLYESTER GEOGRID

- PP Welding Biaxial Geogrid

- HDPE UNIAXIAL GEOGRID

- HDPE GEOCELL

- PLASTIC GRASS PAVER

- DRAINAGE NET

- GCL

- PP FIBERS

- GEOMAT

- Rubber tracked robot chassis/robot undercarriage

- Add: EAST OF TAIDONG ROAD,TAIAN,SHANGDONG,CHINA

- Tel: 86-538-8565299

- Fax: 86-538-8565299

- Email: inquiry@cncadeer.com doris@cncadeer.com

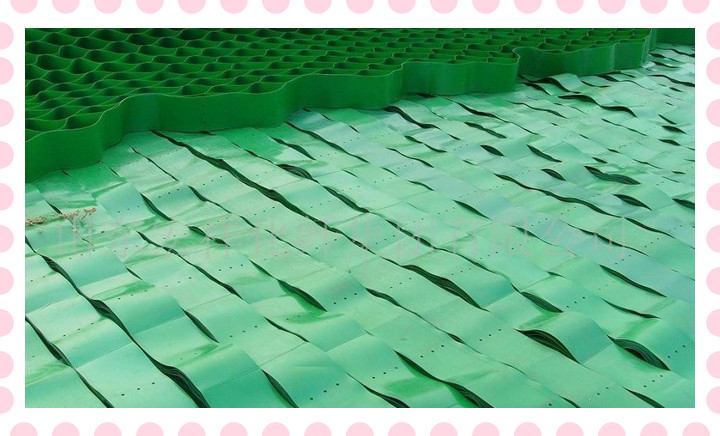

GEOCELL for retaining wall

- Cell Height: 50mm,75mm,100mm,150mm,200mm

- Welding Distance:330-1000mm

- Surface Textured Or Smooth

- Color: Black,Brown,Green

- Product description: GEOCELL for retaining wall 1.Material: HDPE 2.Cell height: 50mm,75mm,100mm,150mm,200mm,250mm 3.Welding distance: 300mm,330mm,400mm,440mm,450mm,500mm,600mm,660mm-1000mm 4.Sheet thickness:1.1

Product introduction

GEOCELL for retaining wall

Specification:

|

Polymer Density |

High Density Polyethylene with density of 0.935 - 0.965 g/cm3 ASTM D 1505 |

|

Environmental Stress Crack Resistance |

> 4000 hours ASTM D 1693 |

|

Carbon Black Content |

Carbon black content 1.5% - 2.0% ASTM D 1603 |

|

Sheet Thickness |

Smooth:1.1mm,1.2mm,textured:1.5mm ,1.7mm ASTM D 5199 |

|

Cell Details |

welding distance:330-1000mm |

|

Cell Depth |

50-250mm |

|

Seam Peel Strength |

As per US Army Corps of Engineer's Report GL-86-19 Appendix A |

|

Seam Hang Strength |

A 100mm wide seam sample supports a 72.5 kg load for a minimum of 30 days in an ambient room temperature environment. |

|

Certification |

CE ,ISO |

|

Classification |

1. smooth surface without hole 2. smooth surface with hole 3. textured surface with hole 4. textured surface without hole |

Applying Area

1.Be used for firm the roadbed of railroad;

2.Be used for firm highway soft foundation handling;

3.Be used for dike and retaining wall, which can bear load force;

4.Be used to harness the shoal water runway;

5.As pipeline and the sewer's propping up structure;

6.Be used for mixed type retaining wall that prevent the slope from falling

down and bear load force;

7.Be used for independent wall, dock and breakwater;

8.Be used to harness the desert, beach and riverbed ,river bank

HDPE Geocell Technical Data

|

|

Height (mm) |

Welding distance (mm) |

Sheet thickness(mm) |

Tensile yield strength of the cell≥(MPa) |

Seam peel strength≥(N) |

|

|

smooth |

textured |

|||||

|

GS50-400 |

50 |

400 |

1-1.1 |

1.4-1.5 |

20 |

500 |

|

GS100-400 |

100 |

400 |

1-1.1 |

1.4-1.5 |

20 |

1000 |

|

GS150-400 |

150 |

400 |

1-1.1 |

1.4-1.5 |

20 |

1500 |

|

GS200-400 |

200 |

400 |

1-1.1 |

1.4-1.5 |

20 |

2000 |

|

GS75-330 |

75 |

400 |

1-1.1 |

1.4-1.5 |

20 |

750 |

|

GS100-330 |

100 |

400 |

1-1.1 |

1.4-1.5 |

20 |

1000 |

|

GS150-330 |

150 |

400 |

1-1.1 |

1.4-1.5 |

20 |

1500 |

|

GS200-330 |

200 |

400 |

1-1.1 |

1.4-1.5 |

20 |

2000 |

High Strength HDPE Geocell Technical Data

|

NO. |

Test Item |

Unit |

Index |

|

1 |

Band tensile strength |

MPa |

≥200 |

|

2 |

Tensile strength at connecting |

N/cm |

≥150 |

|

3 |

Break elongation |

% |

≤15 |

As for other specification, you may contact me directly for further

information. .

cadeer

cadeer